Unfold the 3D printing Technology

3D printing, a Fad or the future

3D printing, a fad or the future

Posted on 17th March 2022

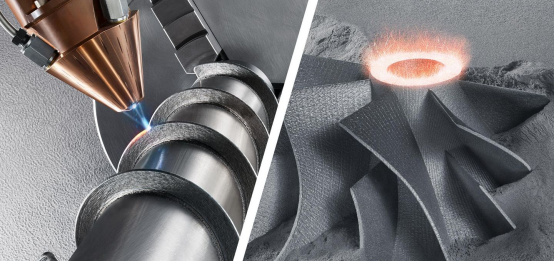

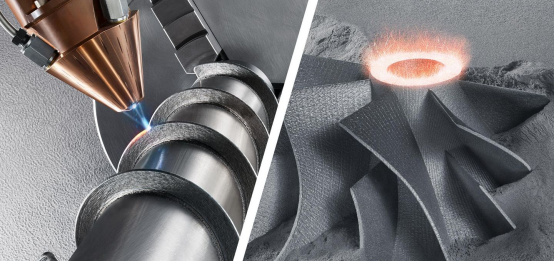

Additive Manufacturing metal parts with intense laser

3D Printing, A Technology That Has The Potential To Take The World By Storm? This Is Not The First Time The World Has Been Introduce With A Technology With Such Impact. So Is 3D Printing A Fad? Or The Future?

As the industry evolve, new technology emerge to improve and refine the efficiency of the production line. 3D printing, also known as additive manufacturing (AM) is one of the key building component and technology trend heralding the Industrial Revolution 4.0 (IR4.0). So what makes 3D printing to cause such an impact and are considering one of the main pillars in the IR4.0? The answer is speed and flexibility. 3D printing has many names, rapid prototyping is one of it. As its name suggest, 3D printing is a technology that are capable to create prototypes in a swifter manner. While working conjunction with the Computer Aided Design (CAD) software, a spark of an idea can come to life in matters of hours or days. This revolutionised the way we manufacture and deliver products across the globe. Any person could have the newest, leading-edge product at the mere touch of a button. Not only it will improve our live, it can also transform it in a way that we couldn’t even fathomed.

“3D printing is revolutionising industries as we speak, from fashion industry to biomedical industry, from consumers to space exploration, and the revolution is still afoot. In order to strive in the tremendous competitive industries, many companies are now utilising this technology as an innovative and effective tool to increase their productivity.

Nike, world’s largest shoe manufacturer decide to bring in the 3D printing technology into the footwear industry in 2013. As all the athletes demand a faster and lighter shoe to improve their physical performance, Nike seize the opportunity to design and fabricate a custom-made plate for the cleats that enhanced the players’ form and speed. After experimenting with the technology, they designed and fabricated their first 3D printed footwear with Selective Laser Sintering (SLS). SLS is one of the 3D printing technology that uses laser to sinter tiny grains of powder and binds them together layer by layer to form a 3D object. With the aid of this technology, they successfully developed and released the NIKE Vapor Laser Talon that weighed a mere 156 grams, successfully reduce the weight while provide optimal traction in the field. After realising the potential of 3D printing, Nike decided to make a bold choice, investing hugely into 3D printing and shift its focus from traditional manufacturing into exploring more possibilities in additive manufacturing.

The sport's first 3D printed plate: Nike vapor laser talon

Space exploration has always been an exciting idea. It’s the humanity natures to explore the unknown and discover new worlds so is the National Aeronautics and Space Administration (NASA) goals. Conquering the Mars is the next grand plan NASA have in mind, and this mission isn’t far ahead. The Desert RATS (Research and Technology Studies) built a Space Exploration Rover with the aid of the 3D printing technology. This next-generation rover are capable of supporting human life on asteroid and Mars. The rover is about a size of a Hummer and what’s so special about it is that it has over 70 parts that were 3D printed with the Fused Deposition Modelling (FDM) technology. These 3D printed part were printed with high-performance Polymer such as ABS, PCABC, and polycarbonate. The capability and the versatility of the rover were put to the test, NASA astronaut and engineering brought it to the Arizona desert, manoeuvring the unforgiving terrain as the wind and sun beat down and the temperature swing from one extreme to another. Steering it over rocks and sands, up and down hills in an environment that simulates the brutal condition of the Martian terrain. With the implementation of the FDM technology, lightweight and complex part can be produce while remaining the high level of ruggedness.

NASA RATS Rover that has over 70 3D printed parts

The additive manufacturing market was forecasted at $15.8 billion in year 2020 and were forecast to reach $35.6 billion at year 2024. To capitalize on this massive market opportunity, companies are dipping their toes in the 3D printing waters by adopting this technology to innovate and transform their manufacturing process. With the aid of this technology, companies and enterprise can produce customised, lightweight, and complex design and allow manufacturer to create innovative products faster, cheaper, and en masses. Ergo, 3D printing is the future to come, to transform and to improve the current method of traditional manufacturing.